Reaction Engines Ltd. is, with some European Space Agency funding (recently 1 million Euros, 6 million so far), developing the SABRE air-breathing/liquid oxygen (LOX) rocket hybrid. They've been working on it for quite some time, and it looks like they've made enough progress to be 'noticed' by the aerospace community. For that investment RE now has working key subsections of the SABRE - the air pre-cooler and the turbo-compressor that condenses it to LOX.

Basically, this is a good candidate to power a single stage to orbit spacecraft (SSTO) that would roll out on a conventional runway, fly to Mach 5.5 at 25km altitude gathering and liquefying atmospheric oxygen as it flies. At the listed altitude/speed it would then switch to the stowed LOX and continue as a liquid fuel rocket to orbit or to a suborbital track for transcontinental flights.

Link.....

Basically, this is a good candidate to power a single stage to orbit spacecraft (SSTO) that would roll out on a conventional runway, fly to Mach 5.5 at 25km altitude gathering and liquefying atmospheric oxygen as it flies. At the listed altitude/speed it would then switch to the stowed LOX and continue as a liquid fuel rocket to orbit or to a suborbital track for transcontinental flights.

Link.....

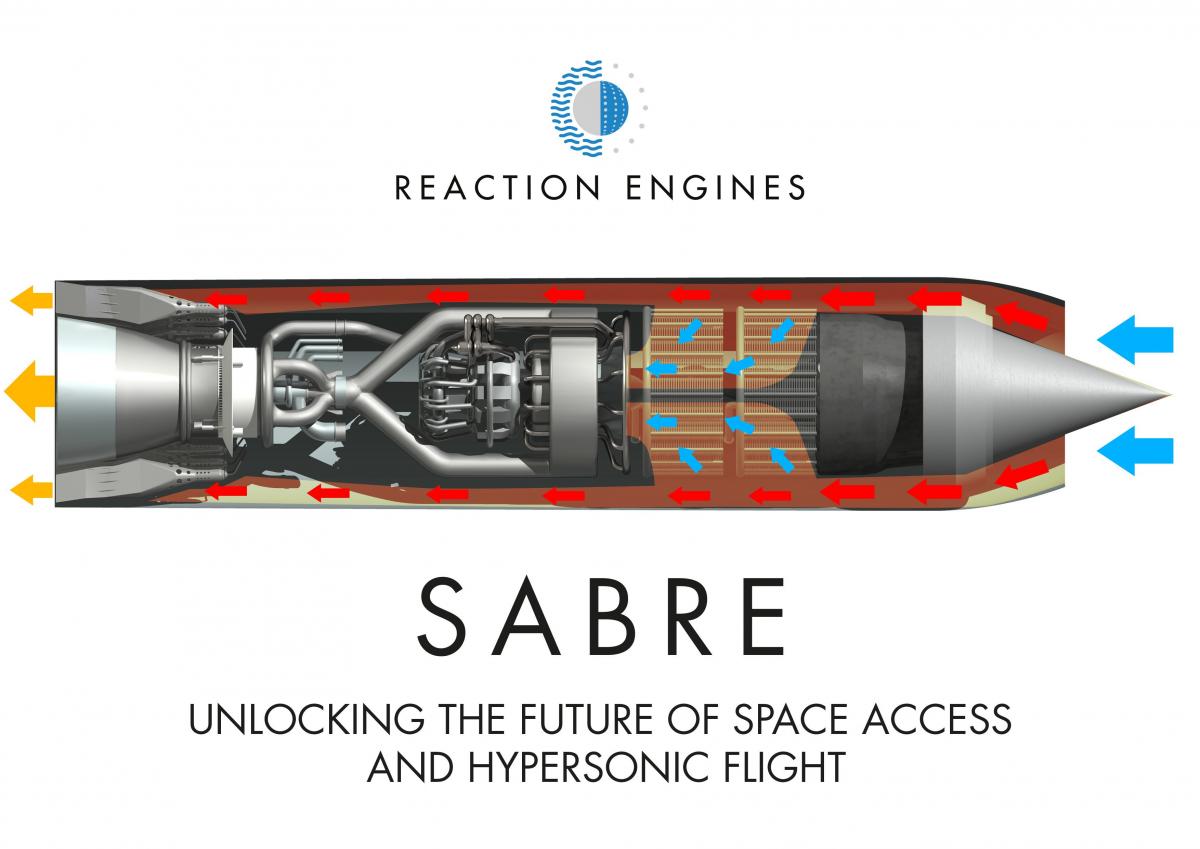

The Sabre Engine

A Hybrid Airbreathing / Rocket Engine, Sabre Represents a Huge Advance over LACE Technology.

In the past, attempts to design single stage to orbit rockets have been unsuccessful largely due to the weight of oxidiser such as liquid oxygen. To reduce the quantity of oxidiser that a vehicle is required to carry it is (one possible solution) useful to be able to use atmospheric oxygen in the combustion process. The Sabre engine does this, allowing two mode operation - both airbreathing and conventional rocket type operation. This is made possible through a synthesis of elements from rocket and gas turbine technology.

The design of Sabre evolved from liquid-air cycle engines (LACE) which have a single rocket combustion chamber with associated pumps, preburner and nozzle which are utilised in both modes. LACE engines employ the cooling capacity of the cryogenic liquid hydrogen fuel to liquefy incoming air prior to pumping. Unfortunately, this type of cycle necessitates very high fuel flow.

These faults are avoided in the Sabre engine, which only cools down the air to the vapour boundary and avoids liquefaction. This allows the use of a relatively conventional turbocompressor and avoids the requirement for an air condenser.

The Sabre engine is essentially a closed cycle rocket engine with an additional precooled turbo-compressor to provide a high pressure air supply to the combustion chamber. This allows operation from zero forward speed on the runway and up to Mach 5.5 in air breathing mode during ascent. As the air density falls with altitude the engine eventually switches to a pure rocket propelling Skylon to orbital velocity (around Mach 25).

Air collection is via a simple conical two shock inlet with a translating centrebody to maintain shock-on-lip conditions. The centrebody moves forward to close the inlet for re-entry. A bypass system is used to match the variable captured air flow to the engine demand. This bypass flow is reheated in order to recover the momentum lost through the capture shock system.

The thrust during airbreathing ascent is variable but around 200 tonnes. During rocket ascent this rises to 300 tonnes but is then throttled down towards the end of the ascent to limit the longitudinal acceleration to 3.0g.

A Hybrid Airbreathing / Rocket Engine, Sabre Represents a Huge Advance over LACE Technology.

In the past, attempts to design single stage to orbit rockets have been unsuccessful largely due to the weight of oxidiser such as liquid oxygen. To reduce the quantity of oxidiser that a vehicle is required to carry it is (one possible solution) useful to be able to use atmospheric oxygen in the combustion process. The Sabre engine does this, allowing two mode operation - both airbreathing and conventional rocket type operation. This is made possible through a synthesis of elements from rocket and gas turbine technology.

The design of Sabre evolved from liquid-air cycle engines (LACE) which have a single rocket combustion chamber with associated pumps, preburner and nozzle which are utilised in both modes. LACE engines employ the cooling capacity of the cryogenic liquid hydrogen fuel to liquefy incoming air prior to pumping. Unfortunately, this type of cycle necessitates very high fuel flow.

These faults are avoided in the Sabre engine, which only cools down the air to the vapour boundary and avoids liquefaction. This allows the use of a relatively conventional turbocompressor and avoids the requirement for an air condenser.

The Sabre engine is essentially a closed cycle rocket engine with an additional precooled turbo-compressor to provide a high pressure air supply to the combustion chamber. This allows operation from zero forward speed on the runway and up to Mach 5.5 in air breathing mode during ascent. As the air density falls with altitude the engine eventually switches to a pure rocket propelling Skylon to orbital velocity (around Mach 25).

Air collection is via a simple conical two shock inlet with a translating centrebody to maintain shock-on-lip conditions. The centrebody moves forward to close the inlet for re-entry. A bypass system is used to match the variable captured air flow to the engine demand. This bypass flow is reheated in order to recover the momentum lost through the capture shock system.

The thrust during airbreathing ascent is variable but around 200 tonnes. During rocket ascent this rises to 300 tonnes but is then throttled down towards the end of the ascent to limit the longitudinal acceleration to 3.0g.

Fractal Design Arc Mini R2, 3800X, Asus B450M-PRO mATX, 2x8GB B-die@3800C16, AMD Vega64, Seasonic 850W Gold, Black Ice Nemesis/Laing DDC/EKWB 240 Loop (VRM>CPU>GPU), Noctua Fans.

Fractal Design Arc Mini R2, 3800X, Asus B450M-PRO mATX, 2x8GB B-die@3800C16, AMD Vega64, Seasonic 850W Gold, Black Ice Nemesis/Laing DDC/EKWB 240 Loop (VRM>CPU>GPU), Noctua Fans.

Comment