Sometimes it's the little things that matter;

The HurriQuake nail

Article on the creator and the full story;

The HurriQuake nail

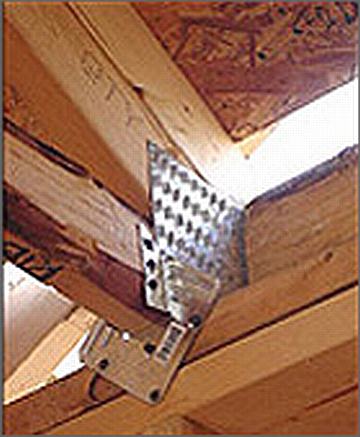

Hurricane winds rip apart nailed-together walls, and earthquakes shake houses so violently that a nailhead can pull straight through a piece of plywood. Since we can’t stop natural disasters, Bostitch engineer Ed Sutt has dedicated his career to designing a better nail. The result is the HurriQuake, and it has the perfect combination of features to withstand nature’s darker moods. The bottom section is circled with angled barbs that resist pulling out in wind gusts up to 170 mph. This “ring shank†stops halfway up to leave the middle of the nail, which endures the most punishment during an earthquake, at its maximum thickness and strength. The blade-like facets of the nail’s twisted top—the spiral shank—keep planks from wobbling, which weakens a joint. And the HurriQuake’s head is 25 percent larger than average to better resist counter-sinking and pulling through. The best part: It costs only about $15 more to build a house using HurriQuakes. $45 per 4,000

Sutt’s bosses at Bostitch must be happy too. The company is selling every HurriQuake nail it produces and has been doubling production capacity every month. Although the nail is currently available only in the Gulf region (it adds about $15 to the cost of an average 2,000-square-foot house), the company is adding new production lines to meet nationwide demand. Meanwhile, the nail is getting rave reviews from building-technology experts.

). The policy then, for villas, is to have a super-rigid structure which has a heavy inertial weight in the roof but can move at ground level. In my house, the concrete roof beam has a section of 60 x 40 cm with 36 2 cm reinforcements in a cage structure. This is triangulated to 9 columns with attachments at 3 points - and it is just less than 10 m long. I'm in a class 2 earthquake zone (historically <6 Richter). Those in class 1 (>6 Richter) are even stronger and apartment/office blocks are limited to 5 storeys. Nicosia is in class 3 and has the highest "skyscrapers" (I think the highest is ~10 storeys, but am not sure; I don't know whether there is a restriction on height for this or any other reason).

). The policy then, for villas, is to have a super-rigid structure which has a heavy inertial weight in the roof but can move at ground level. In my house, the concrete roof beam has a section of 60 x 40 cm with 36 2 cm reinforcements in a cage structure. This is triangulated to 9 columns with attachments at 3 points - and it is just less than 10 m long. I'm in a class 2 earthquake zone (historically <6 Richter). Those in class 1 (>6 Richter) are even stronger and apartment/office blocks are limited to 5 storeys. Nicosia is in class 3 and has the highest "skyscrapers" (I think the highest is ~10 storeys, but am not sure; I don't know whether there is a restriction on height for this or any other reason).

Comment