Finally; an adhesive that uses the van der Waals interaction to stick, the same 'force' that holds solids and liquids together.

Anyone for a Spidy-suit?

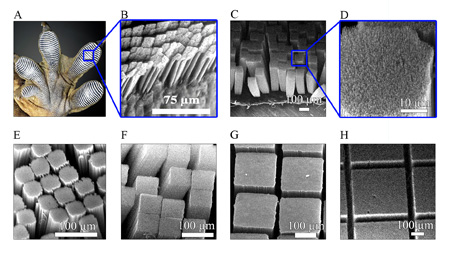

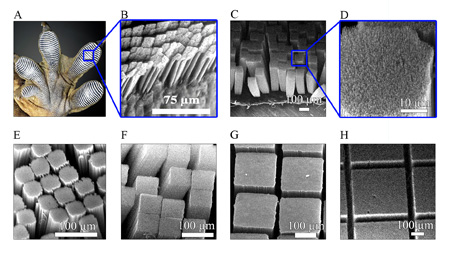

Microfabricated aligned multiwalled carbon nanotube setae and spatulas. (A) Optical picture of gecko foot showing that the setae are arranged in many lobes along the foot. (B) SEM image of natural gecko setae terminating into thousands of smaller spatulas. (E–H) SEM images of synthetic setae of width 50 (E), 100 (F), 250 (G), and 500 (H) µm. (C and D) Side views (C) and higher magnification SEM image (D) of the 100 µm setae. Image courtesy of the University of Akron.

Link....

Anyone for a Spidy-suit?

Microfabricated aligned multiwalled carbon nanotube setae and spatulas. (A) Optical picture of gecko foot showing that the setae are arranged in many lobes along the foot. (B) SEM image of natural gecko setae terminating into thousands of smaller spatulas. (E–H) SEM images of synthetic setae of width 50 (E), 100 (F), 250 (G), and 500 (H) µm. (C and D) Side views (C) and higher magnification SEM image (D) of the 100 µm setae. Image courtesy of the University of Akron.

Link....

Nanotube adhesive sticks better than a gecko's foot

Mimicking the agile gecko, with its uncanny ability to run up walls and across ceilings, has long been a goal of materials scientists. Researchers at Rensselaer Polytechnic Institute and the University of Akron have taken one sticky step in the right direction, creating synthetic “gecko tape†with four times the sticking power of the real thing.

In a paper published in the June 18–22 issue of the Proceedings of the National Academy of Sciences, the researchers describe a process for making polymer surfaces covered with carbon nanotube hairs. The nanotubes imitate the thousands of microscopic hairs on a gecko’s footpad, which form weak bonds with whatever surface the creature touches, allowing it to “unstick†itself simply by shifting its foot.

For the first time, the team has developed a prototype flexible patch that can stick and unstick repeatedly with properties better than the natural gecko foot. They fashioned their material into an adhesive tape that can be used on a wide variety of surfaces, including Teflon.

Pulickel Ajayan, the Henry Burlage Professor of Materials Science and Engineering at Rensselaer, and Lijie Ci, a postdoctoral research associate in Ajayan’s lab, created the material in collaboration with Ali Dhinojwala, professor of polymer science at the University of Akron, and University of Akron graduate students Liehui Ge and Sunny Sethi.

“Several people have tried to use carbon nanotube films and other fibrous structures as high-adhesive surfaces and to mimic gecko feet, but with limited success when it comes to realistic demonstrations of the stickiness and reversibility that one sees in gecko feet,†Ajayan said. “We have shown that the patchy structures from micropatterned nanotubes are essential for this unique engineering feat to work. The nanotubes also need to be the right kind, with the right dimensions and compliance.â€

“Geckos inspired us to develop a synthetic gecko tape unlike any you’ll find in a hardware store,†Dhinojwala says. “Synthetic gecko tape uses ‘van der Waals interactions’ — the same interactions that hold liquids and solids together — to stick to a variety of surfaces without using sticky glues.â€

The material could have a number of applications, including feet for wall-climbing robots; a dry, reversible adhesive in electronic devices; and outer space, where most adhesives don’t work because of the vacuum.

Source: Rensselaer Polytechnic Institute

Mimicking the agile gecko, with its uncanny ability to run up walls and across ceilings, has long been a goal of materials scientists. Researchers at Rensselaer Polytechnic Institute and the University of Akron have taken one sticky step in the right direction, creating synthetic “gecko tape†with four times the sticking power of the real thing.

In a paper published in the June 18–22 issue of the Proceedings of the National Academy of Sciences, the researchers describe a process for making polymer surfaces covered with carbon nanotube hairs. The nanotubes imitate the thousands of microscopic hairs on a gecko’s footpad, which form weak bonds with whatever surface the creature touches, allowing it to “unstick†itself simply by shifting its foot.

For the first time, the team has developed a prototype flexible patch that can stick and unstick repeatedly with properties better than the natural gecko foot. They fashioned their material into an adhesive tape that can be used on a wide variety of surfaces, including Teflon.

Pulickel Ajayan, the Henry Burlage Professor of Materials Science and Engineering at Rensselaer, and Lijie Ci, a postdoctoral research associate in Ajayan’s lab, created the material in collaboration with Ali Dhinojwala, professor of polymer science at the University of Akron, and University of Akron graduate students Liehui Ge and Sunny Sethi.

“Several people have tried to use carbon nanotube films and other fibrous structures as high-adhesive surfaces and to mimic gecko feet, but with limited success when it comes to realistic demonstrations of the stickiness and reversibility that one sees in gecko feet,†Ajayan said. “We have shown that the patchy structures from micropatterned nanotubes are essential for this unique engineering feat to work. The nanotubes also need to be the right kind, with the right dimensions and compliance.â€

“Geckos inspired us to develop a synthetic gecko tape unlike any you’ll find in a hardware store,†Dhinojwala says. “Synthetic gecko tape uses ‘van der Waals interactions’ — the same interactions that hold liquids and solids together — to stick to a variety of surfaces without using sticky glues.â€

The material could have a number of applications, including feet for wall-climbing robots; a dry, reversible adhesive in electronic devices; and outer space, where most adhesives don’t work because of the vacuum.

Source: Rensselaer Polytechnic Institute

Comment